CONVERSION FROM DIESEL TO ELECTRIC

IN CONSTRUCTION MACHINERY

Eco-friendly solutions, lower costs, and sustainable energy are possible with us!

EDM e-mobility is a pioneering solution partner in converting construction machinery from diesel to electric. With our innovative technologies and engineering expertise, we reduce carbon emissions while achieving significant savings in operating costs. With over 200 successful conversion projects, we are building a sustainable future.

By analyzing your business's field conditions and electrical infrastructure, we design and implement customized electrical infrastructure and machine conversions customized to your needs, providing the ideal solutions for your site and machinery.

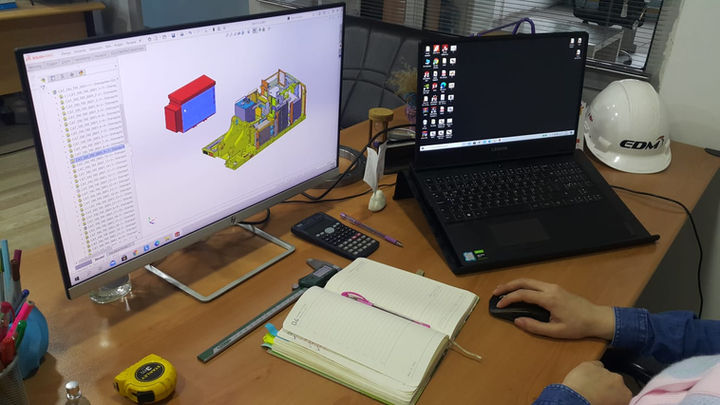

01

Planning,

Project, and Design

The machine's operating conditions are analyzed, engineering calculations are performed, and components compatible with the electric system are designed to prepare the machine for conversion.

02

Diesel

Equipment Disassembly

The machine's diesel engine and related components are dismantled in accordance with engineering principles, preparing it for transition to the electric system.

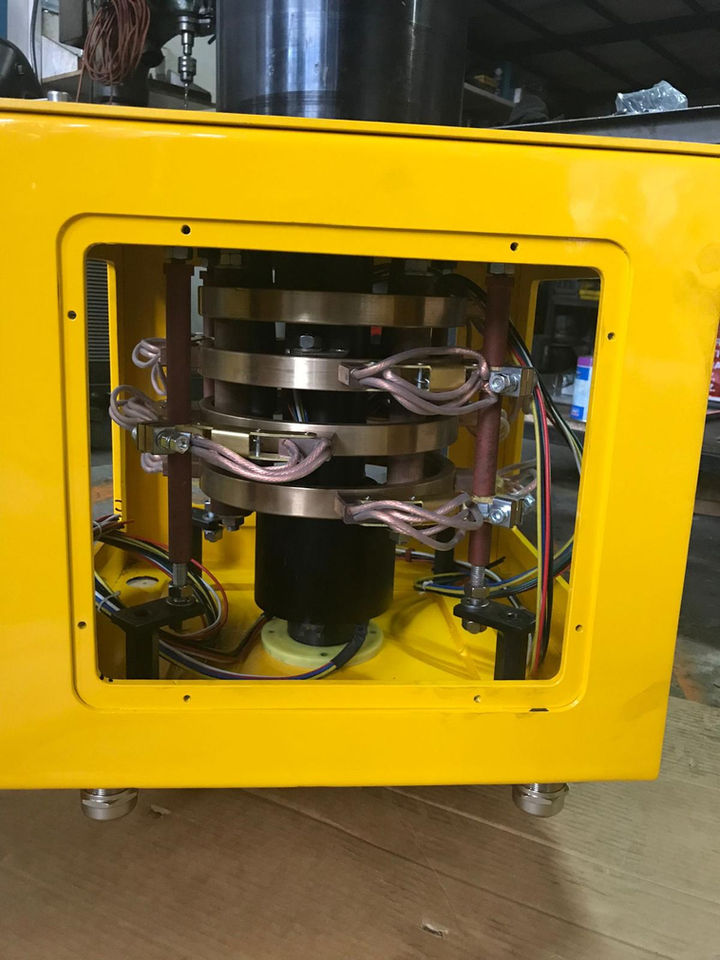

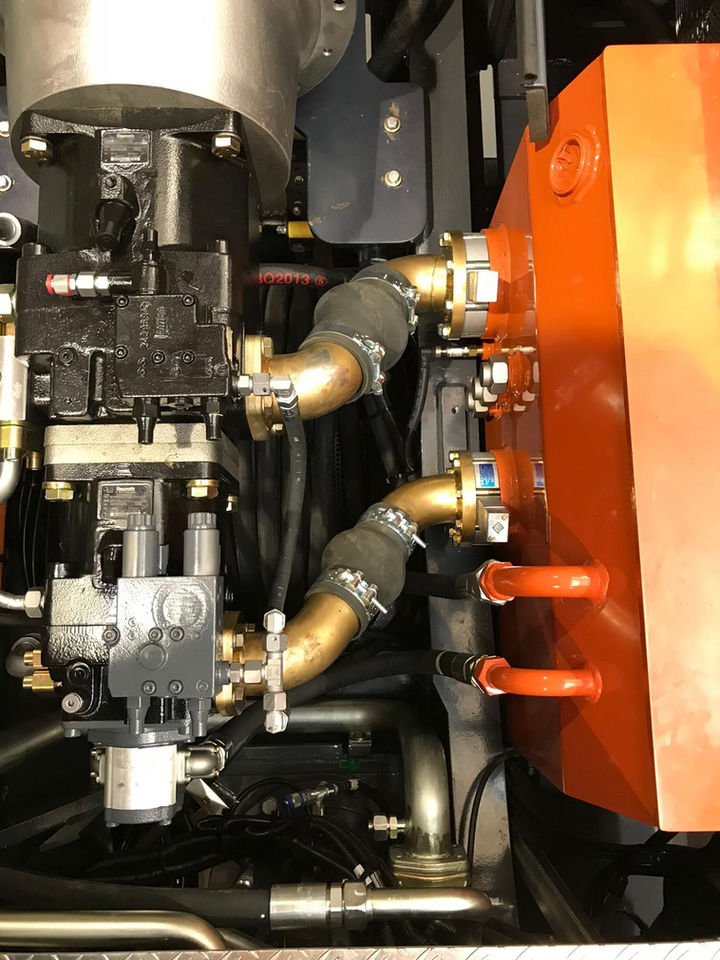

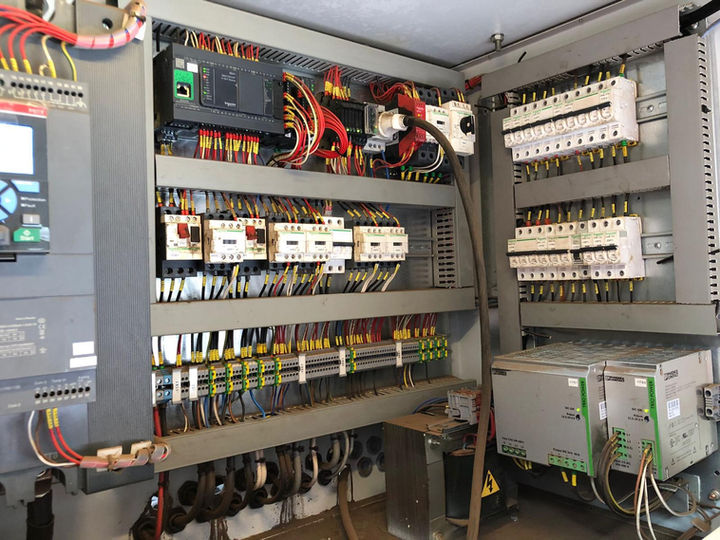

03

Installation of

Electrical Equipment

The electric motor, coupling systems, and other components are meticulously assembled to ensure seamless integration into the machine’s new electric system.

Electric Construction Machinery Conversion Process

An Innovative Solution Step by Step

The electric conversion process of construction machinery is completed through the stages of planning, project design, production, quality control, and assembly. This comprehensive process ensures that your machine is transformed into an eco-friendly, cost-effective, and high-performance system.

04

Testing and

On-Site Completion

The converted machine undergoes comprehensive testing to ensure performance and safety compliance. Once approved, the system is delivered ready for use.

%75

MINIMUM

FUEL BUDGET SAVINGS

%50

UP TO

OPERATIONAL SAVINGS

%35

APPROXIMATELY

REDUCTION IN CARBON EMISSIONS

%0

CO₂

EMISSION OUTPUT

Advantages of Conversion

We achieve up to 75% savings in fuel costs and up to 50% reduction in operational expenses, while reducing carbon emissions by approximately 35%. Furthermore, you are able to recover the costs of the conversion in a short period of time.

CONVERSION COMPLETED

EXCAVATOR NOW OPERATES ON ELECTRICITY!

OUR PROJECTS

We have successfully implemented our electric conversion system in over 200 projects, including machines from leading brands like Hitachi and Atlas. As an industry leader, we have reached a broad customer portfolio.

59 CONVERSIONS

44 CONVERSIONS

33 CONVERSIONS

17 CONVERSIONS

12 CONVERSIONS

25 CONVERSIONS

19 CONVERSIONS

In Electric Conversion

15 Years of Experience, Countless Applications...

EDM e-mobility offers a wide range of conversion services for construction machinery, including excavators, loaders, trucks, and auxiliary equipment. We provide solutions across various industries, including:

-

Mining Sites

-

Recycling Facilities

-

Steel Mills

-

Particleboard & MDF Factories

-

Power Plants

By delivering sustainable and efficient projects, we create value for many sectors.

TODAY, DREAMS HAVE COME TRUE...

When our company was founded, the idea of converting a diesel construction machine to electric for the first time in Turkey and the world was the core vision.

Founded in 2010 as EDM Dış Ticaret Makine Sanayi A.Ş., based on the initials of 'Electrical Drive Machine,' our company has been serving as the Turkish representative of Atlas GmbH and E-Crane while also starting to implement electric conversion systems.

We have successfully completed the installation of systems and components developed through our in-house R&D and applications, maintaining industry leadership to this day.

In line with the growing demand both in Turkey and worldwide, our company has completed the electric conversion of over 200 diesel construction machines.

As EDM e-mobility, we are the OEM product provider and solution partner for Atlas industrial excavators at their Bremen/Germany factory. Under an international supplier agreement with HITACHI Construction Machinery, we provide electric conversion services worldwide on behalf of HITACHI.

Our goal is to convert diesel construction machines to electric in all areas of use in our rapidly industrializing and climate-changing world.

We specialize in the wired electric and battery-powered conversion of all construction machinery and off-road trucks…

Who Are We?

We are a global leader aiming to pioneer in the wired electric and battery-powered conversions of construction machinery.

What Do We Provide?

Through electric system conversion, we ensure performance continuity, energy savings, zero emissions, minimal maintenance costs, and customer satisfaction.

What Do We Do?

We carry out electric system conversions for industrial excavators and construction machinery, ensuring maximum performance and high quality.

What Are Our Goals?

Our goal is to benefit both our customers and the world we live in by converting construction machinery to electric systems with an innovative approach.

An international supplier agreement has been signed between HITACHI Construction Machinery and EDM e-mobility for the electric conversion of diesel excavators.

Electrical System Integrator

Under this agreement, kits for the turnkey electric conversion of existing diesel excavators, particularly in the mining sector within the EMEA region, will be produced, assembled, and commissioned.

Our company, EDM e-mobility, has achieved many firsts both globally and in Turkey, with 15 years of experience and over 200 electric construction machinery conversions completed. We are proud to share this expertise and accomplishments through the HITACHI & EDM collaboration worldwide.

Our company, a global leader in electric conversion of construction machinery,

Global Brands We Partner With

serves as a solution partner for the manufacturers of world-renowned brand such as German Atlas GmbH industrial excavators providing electric versions on their production lines.

Additionally, LVKON and EDM e-mobility have signed an agreement for the distribution of electric and hybrid vehicle drive systems in Turkey.

Turkey Distributor

Manufacturer

As part of this agreement, EDM e-mobility will serve as the authorized distributor of LVKON's electric and hybrid vehicle drive systems in Turkey, providing sales, distribution, and technical support for the products.

EDM e-mobility has successfully delivered numerous electric conversion projects both globally and in Turkey, maintaining its leading position in the industry with 15 years of experience and over 200 converted electric construction machines. We are proud to bring this expertise and know-how to the Turkish market through our collaboration with LVKON.

KOMATEK 17th International Construction and Construction Machinery Fair

We participated in the KOMATEK Fair, one of the most important gatherings in the industry! At our booth, we introduced our electric conversion solutions and had productive meetings with our visitors. We would like to thank everyone for their intense interest!

Shots of the Conversion

Innovation in Every Frame

Construction machinery powered by electricity instead of diesel fuel provides high torque and continuous performance. With silent operation, low maintenance costs, and zero carbon emissions, it offers an eco-friendly and sustainable solution, making your work processes more efficient.

CARBON EMISSION IMPACT OF DIESEL AND ELECTRIC MOTORS

Carbon Footprint: Comparative Technical Calculations and Examples

To see the annual savings and environmental impacts of electric motors in more detail, you can refer to the tables below.

You can also calculate your carbon emission reduction based on your machine's kW power and operating hours.

A project of converting to a 100 kW electric motor provides

approximately 42 kg less carbon release per hour.

During continuous operation of 12-hour per day for 300 days/year,

total carbon footprint reductions is 152 tons per year.

100 kW

electric motor:

CO₂ emissions per year= 300g CO₂/kWh × 100kW × 12 hour × 300 day= 108 tons CO₂

100 kW

diesel motor:

Fuel consumption per hour=100kW×0.27 liter/kWh=27 liter of diesel

CO₂ emissions per year =27 liter × 2.68kg CO₂/liter × 12 hour × 300 day =260 tons CO₂

Diesel

2.263 Tons

Total Fuel Consumption: 544,560 liters

Electric

777 Tons

Total Power Consumption: 2,592,000 kWh

%65

Up to Carbon Footprint Reduction

1.450 kW

diesel motor:

Fuel consumption per hour=1.450kW×0.27 liters/kWh =391 liters of diesel

Annual Diesel Consumption: 544,560 liters

CO₂ Emissions (annually)=391 liters×2.68 kg CO₂/liter×12 hours×300 days×0.6=2,263 tons CO₂

1.200 kW

electric motor:

CO₂ Emissions (annually)=300 g CO₂/kWh × 1,200 kW × 12 hours × 300 days × 0.6 = 777 tons CO₂

Annual Power Consumption: 2,592,000 kWh

Diversity = 0.6

The converted HITACHI EX 3600 has provided significant benefits.

How it works?

In wired conversion processes, we convert the electricity coming to your facility into suitable voltage levels such as 400V, 690V, or 6600V through transformers. This conversion ensures that your machinery is supplied with the necessary electrical power for operation. Additionally, to meet the energy needs of construction machinery such as mining trucks and loaders, we install custom charging infrastructure at your facility, ensuring these vehicles are charged efficiently. This guarantees that your operations continue seamlessly and efficiently.

OUR PRODUCTS

We offer innovative solutions customized to the needs of your electric construction machinery. With custom-designed Cable Drums, we simplify cable management while the machines are in motion, enhancing operational efficiency. Additionally, our HVAC (Heating, Ventilation, and Air Conditioning) solution maximizes cabin comfort, ensuring that operators can work efficiently. With these innovative solutions, we improve the performance and working conditions of your machinery.

.jpeg)

Use of Cable Drums in

Electric Construction Machinery

Cable drums are essential components in electric construction machinery that simplify cable management. These systems automatically manage the orderly winding and unwinding of cables. Proper cable winding prevents loose cables from spreading across the work area and ensures smooth movement of the machine. This helps prevent cable tangles and potential malfunctions, increasing the machinery's mobility. Especially in heavy equipment like excavators, these systems enhance overall efficiency and functionality, enabling faster and safer operations.

Cable Reel

Slip Ring

Cabin Heater

The Ideal Solution for Cable Management with Advanced Engineering

Our Cable Drum technology ensures that cable management is carried out safely and efficiently. This solution, specifically developed for ideal cable management, enables uninterrupted and highly efficient operations in your machinery.

Proper and secure winding of cables prevents potential disruptions and cable damage in moving machines, thus enhancing the performance of your equipment. All of our Cable Drum systems are meticulously designed and manufactured in-house, ensuring that each solution meets the highest quality standards.

Transformer Box

With Strong Connections and Strong Partnerships

Our References

Our long-standing partnerships have been strengthened by the trust we’ve built with our customers and the successful solutions we’ve provided. Leading companies in the industries we work with choose us for our innovative and environmentally friendly approaches.

Each of our references is a testament to the importance we place on quality and customer satisfaction. Join us and become a part of our strong business network!

ATLAS GMBH GERMANY

-

8 ATLAS MHE 350 (132 kW)

-

4 ATLAS LCE 350 (132 kW)

-

2 ATLAS MHE 250 (90 kW)

-

3 ATLAS MHE 180 (90 kW)

-

5 ATLAS MHE 160 (75 kW)

KAPTAN DEMİR ÇELİK MARTAŞ PORT

-

1 SENNEBOGEN 6180 (560 kW)

-

1 SENNEBOGEN 6120 (355 kW)

-

1 SENNEBOGEN 880 (500 kW)

-

1 SENNEBOGEN 870 (250 kW)

-

3 SENNEBOGEN 835 (160 kW)

MULTIDOCKER SWEDEN

-

CAT 390F&MULTIDOCKER CH1400 (355kW)

HANS VAN DRİEL

-

1 SENNEBOGEN 850 (200 kW)

CEYNAK & CEYPORT

-

2 REGGIANE MHC 200 (560 kW)

-

3 REGGIANE MHC 40 (250 kW)

-

2 REGGIANE MHC 20 (200 kW)

YEŞİLYURT PORT OPERATIONS

-

1 SENNEBOGEN 6180 (560 kW)

-

1 SENNEBOGEN 6130 (355 kW)

-

2 SENNEBOGEN 880 (500 kW)

-

2 SENNEBOGEN 870 (250 kW)

PIRIL CONSTRUCTION

-

2 SENNEBOGEN 835 (160 kW)

EKMAR - EKİNCİLER PORT OPERATIONS

-

2 SENNEBOGEN 880 (500 kW)

NUH ÇİMENTO & ÇİMNAK

-

1 HITACHI 1900 (800 kW)

-

1 HITACHI 1800 (2×355 kW)

-

1 HITACHI 1200 (500 kW)

-

4 KOMATSU 550 (250 kW)

-

1 KOMATSU 450 (200 kW)

MEGAREX – RUSSIA

-

8 ATLAS MHE 550 (200 kW)

-

8 ATLAS MHE 350 (132 kW)

İZMİR DEMİR ÇELİK PORT

-

1 SENNEBOGEN 6180 (560 kW)

-

1 SENNEBOGEN 6120 (355 kW)

-

2 SENNEBOGEN 880 (500 kW)

İM KÖSE MINING

-

6 CATERPILLAR 390 F (400 kW)

-

8 CATERPILLAR 385 C (400 kW)

FERNAS İNŞAAT A.Ş.

-

2 HITACHI 890 (400 kW)

KASTAMONU ENTEGRE

-

1 LIEBHERR 904C (90 kW)

-

1 SENNEBOGEN 821 (90 kW)

ÇELİKLER HOLDING

-

4 HITACHI 1200 (500 kW)

-

1 HITACHI 890 (400 kW)

YATAĞAN TERMİK SANTRALİ

-

8 HITACHI 890 (355 kW)

EFESAN PORT

-

1 GOTTWALD 320 (560 kW)

BLOG AND NEWS

Current news on industry developments, our trade fair participations, and innovations are here!

Get in Touch,

Discover Tailored Solutions Just for You!